Unveiling the Secrets of Tent Fabrics: Insights from TENT FABRIC Manufacturers

I. The Art of Waterproofing in Tent Fabrics

(1) The Pivotal Role of PU Waterproof Coating

(2) DWR Treatment and Silicone Coating: Enhancing Tent Performance

II. A Diverse Array of Tent Fabrics

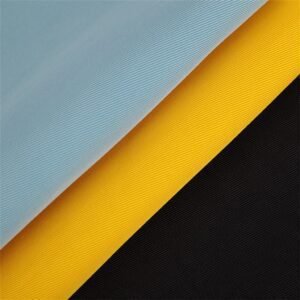

(1) Polyester Tent Fabric: Balancing Cost and Durability

(2) Nylon Tent Fabric: Lightweight Strength for the Adventurous

(3) Nylon 66 Tent Fabric: Premium Performance in Demanding Conditions

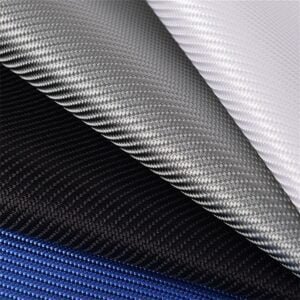

(4) Ripstop Tent Fabric: Reinforced Durability Through Innovation

III. Navigating Fabric Specification Selection

TKANINY ANTYSTATYCZNE

TKANINY WIELOFUNKCYJNE

TKANINY TRUDNOPALNE

TKANINY OLEJOODPORNE

TKANINY NA NIEPOGODĘ

TKANINY O WYSOKIEJ WIDOCZNOŚCI

Suzhou Sikor Industry Co., Ltd to innowacyjne przedsiębiorstwo z siedzibą w Suzhou w Chinach, posiadające szerokie doświadczenie w produkcji wysokowydajnych tkanin z włókien chemicznych.

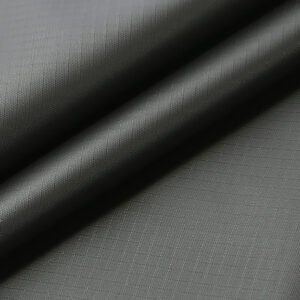

Nasze główne tkaniny obejmują lekkie tkaniny, tkaniny typu ripstop, trwałe i biodegradowalne tekstylia, tkaniny i tkaniny funkcjonalne, zwłaszcza tkaniny funkcjonalne, wodoodporne i oddychające tkaniny, tkaniny zgrzewalne, 3-warstwowe laminaty Tkanina, Przeciwbakteryjny odporny na zapachy i trwały tkanina cordura.

Tkaniny te zostały zaprojektowane tak, aby zapewnić specjalną ochronę i są odpowiednie dla nieformalny strój, odzież sportowa na świeżym powietrzu, odzież robocza. Różne zastosowania, w tym torby, namioty, artykuły kempingowe I przemysłowy wykorzystuje.