Tissus teints dans la masse : des textiles durables

Le procédé de teinture en solution (également appelé teinture dans la masse) a attiré beaucoup d'attention dans le développement de l'industrie textile.

Procédé de teinture dans la masse :

Les tissus teints dans la masse utilisent des fils teints dans la masse. Au cours du processus de filage, des colorants masterbatch sont ajoutés au polymère fondu pour imprégner complètement les fibres de pigments, qui sont ensuite filés, refroidis et étirés pour former des faisceaux de fibres colorées.

Avantages des tissus teints dans la masse :

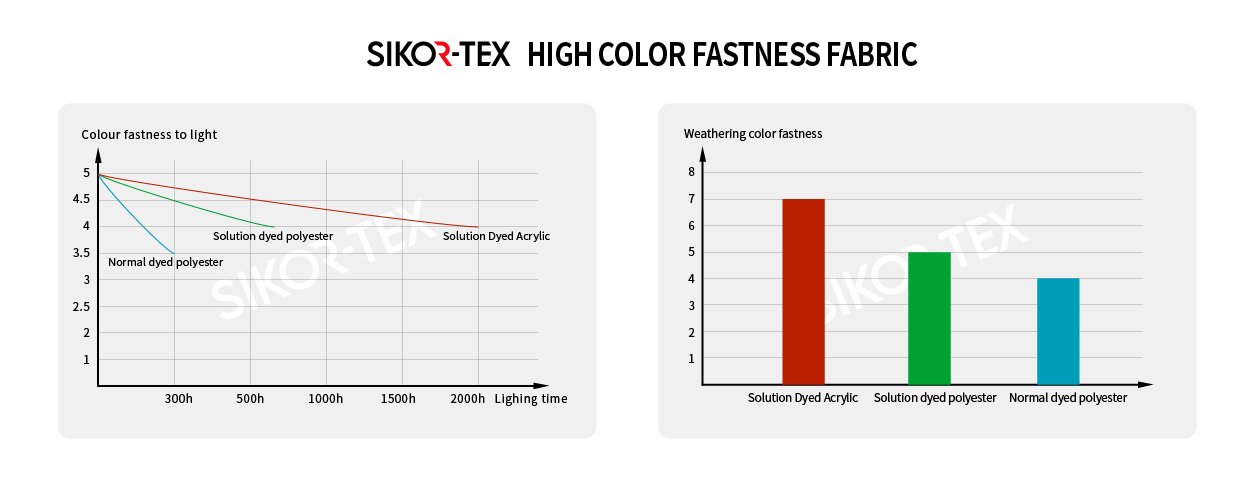

Excellente solidité des couleurs : les tissus teints dans la masse de SIKOR-TEX utilisent un procédé spécial de filage de polyester en solution et leur résistance à la lumière atteint la norme AATCC16-3, UV500 heures, niveau 5. Lorsqu'ils sont utilisés pour des produits d'extérieur tels que des auvents, ils peuvent conserver des couleurs vives et stables pendant longtemps dans différents environnements extérieurs, évitant ainsi efficacement le problème des différences de lots de teinture dans les processus de teinture traditionnels.

Les tissus teints dans la masse ont une couleur extrêmement stable

Les tissus teints dans la masse ont une forte résistance des couleurs à la lumière du soleil et sont remarquables en termes de résistance à la décoloration due aux UV et aux changements de couleur. Par exemple, les tissus publicitaires extérieurs peuvent conserver des couleurs vives même sous une exposition prolongée au soleil.

Les tissus teints dans la masse ont une couleur extrêmement uniforme

Il n'y a pratiquement aucune différence de couleur entre les différents lots, ce qui convient parfaitement à la production textile standardisée à grande échelle, comme la literie d'hôtel et les nappes de restaurant.

Les tissus teints dans la masse ont une forte tolérance

Le tissu teint en solution peut résister à plusieurs lavages et présente une excellente résistance des couleurs aux acides et aux alcalis, et peut s'adapter à des environnements d'utilisation spéciaux tels que les vêtements de travail hospitaliers et les vêtements de protection de laboratoire.

Les tissus teints dans la masse ont une excellente résistance aux intempéries

Ils peuvent être utilisés normalement dans des conditions climatiques difficiles telles que des températures et des chaleurs élevées, un froid et un gel extrêmes, de l'humidité et de la pluie, de la sécheresse et du vent, et ont un large éventail d'applications.

Les tissus teints dans la masse sont respectueux de l'environnement et économisent l'eau

Comme le processus de teinture n'utilise pas d'eau, il réduit considérablement la consommation de ressources en eau et réduit la pollution de l'environnement. C'est un représentant typique des textiles durables.

Les défis actuels de l'industrie textile

Les procédés de teinture traditionnels sont inefficaces et environ 300 000 tonnes de colorants sont rejetées dans les eaux usées chaque année, ce qui pollue gravement l'écologie aquatique. Parallèlement, en raison de sa grande échelle et de ses nombreux procédés, l'industrie textile est l'une des principales sources d'émissions de gaz à effet de serre.

L'importance du processus

Les procédés de teinture dans la masse et de teinture en solution présentent des avantages évidents en termes de protection de l'environnement et de performance des couleurs. Ils répondent non seulement aux besoins des consommateurs modernes en matière de textiles de haute qualité et respectueux de l'environnement, mais aident également les entreprises textiles à faire face à la pression des réglementations environnementales et de la concurrence sur le marché. Dans le contexte du progrès technologique continu, ils conduiront certainement l'industrie textile vers un avenir plus vert et plus durable, apportant de nouveaux changements à la qualité et à l'image environnementale des produits textiles.

Fabricant de tissus haute performance

Suzhou Sikor Industry Co., Ltd est une entreprise innovante dont le siège est à Suzhou, en Chine, avec une vaste expérience dans la production de tissus en fibres chimiques tissés haute performance.

Nos principaux tissus comprennent Tissus Oxford, tissus indéchirables, PU/TPU/PVC tissus enduits, tissus tissés et tissus fonctionnels, en particulier tissus fonctionnels, tissus imperméables et respirants, tissus soudables, tissus laminés à 3 couches, Antibactérien résistant aux odeurs et durable tissu cordura.

Ces tissus sont conçus pour offrir une protection spéciale et conviennent pour vêtement de tous les jours, vêtements de sport en plein air, vêtements de travail. Diverses applications, notamment sacs, tentes, fournitures de camping et industriel les usages.

Contactez-nous

sales@sikortex.com

sales@sikortex.com

En savoir plus sur les tissus écologiques

Tissus recyclables

Tissus en nylon recyclables

Tissus acryliques teints dans la masse