SIKOR-TEX is committed to manufacturing high color fastness and UV resistan fabrics.

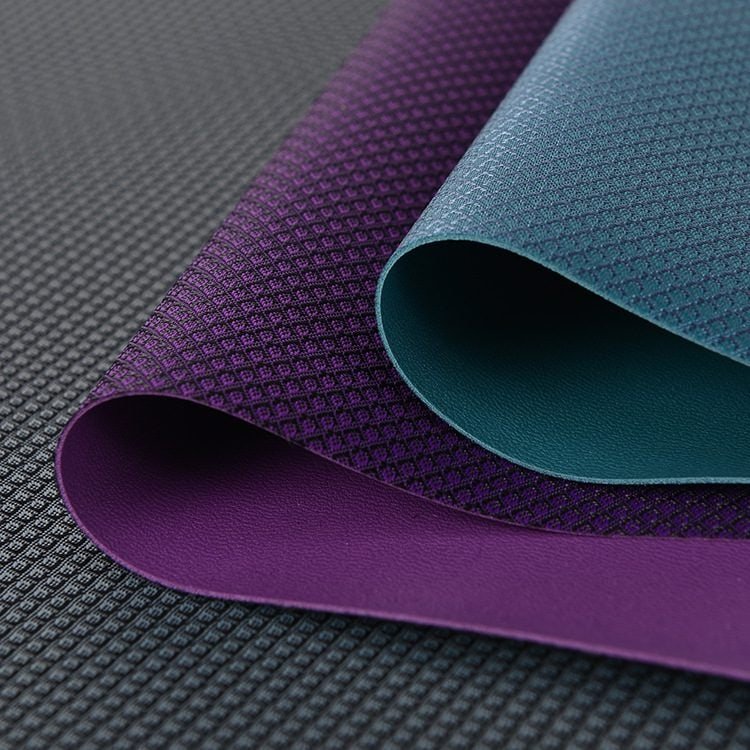

In today’s fast-evolving world, industries demand materials that can withstand the rigors of both environmental and operational challenges. Whether it’s for outdoor applications, industrial coverings, or protective gear, the need for advanced fabrics that offer durability, safety, and performance is critical. Enter the Flame Retardant Anti-UV Oxford Cloth, a cutting-edge textile designed to meet the stringent demands of various industries. This fabric not only protects against harmful UV rays but also offers robust flame-retardant properties, setting a new standard for high-performance textiles.

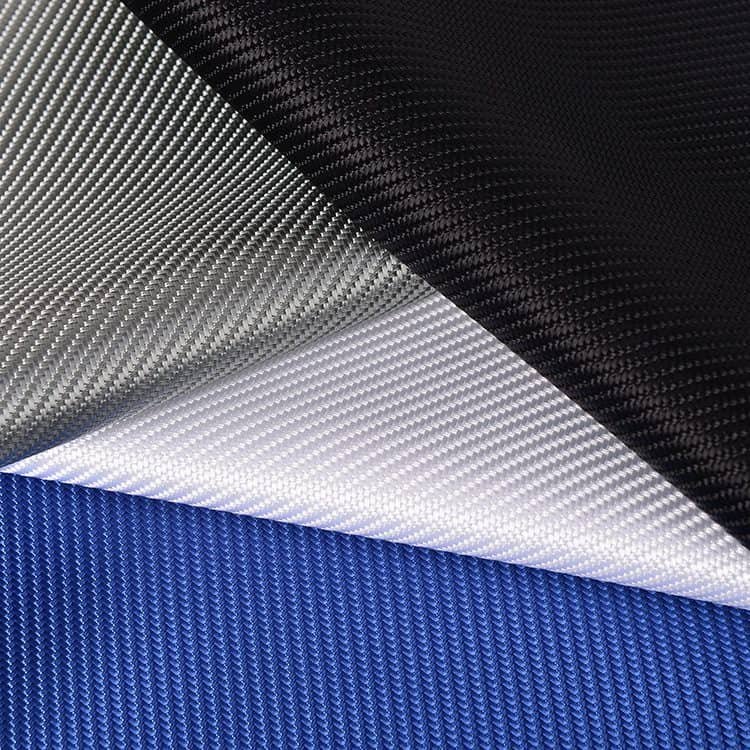

Innovation in Color Fastness: Solution Dyeing Polyester Technology

One of the standout features of our solution dyed fabric is the use of solution-dyed polyester technology. This process is a major leap forward in fabric manufacturing and offers several advantages over traditional dyeing methods.

In conventional dyeing, fabrics are colored after the material is woven, which often leads to uneven color distribution and a propensity for the fabric to fade over time. However, solution dyeing changes the game by integrating color directly into the polyester fibers during production. By adding masterbatch—concentrated pigments and additives—into the molten polyester before it’s extruded into fibers, the color becomes an intrinsic part of the material. This not only enhances the fabric’s color fastness to sunlight but also ensures that the color remains vibrant and consistent over time, even after extensive exposure to UV rays.

This innovative process has far-reaching environmental benefits as well. Traditional dyeing processes consume vast amounts of water and energy, contributing to significant environmental degradation. In contrast, solution dyeing drastically reduces water usage and carbon emissions, making it a more sustainable choice for eco-conscious businesses. The result is a fabric that not only meets the high standards of durability and performance but also aligns with global sustainability goals.

Unparalleled UV Protection: UPF 50+ Performance

The primary function of any UV-protective fabric is to shield the user from the sun’s harmful rays. Our Flame Retardant Anti-UV Oxford Cloth excels in this area, offering an exceptional level of ultraviolet protection. The fabric has undergone rigorous testing, passing the American Association of Textile Chemists and Colorists (AATCC) 16.3-2014 test, with over 500 hours of UV exposure. The results are impressive, achieving a level 5 rating in color fastness and a UPF (Ultraviolet Protection Factor) rating of 50+.

A UPF rating of 50+ is the highest level of UV protection available in fabrics, blocking more than 98% of UVA and UVB rays. This makes our fabric an ideal choice for applications where prolonged exposure to sunlight is a concern, such as in outdoor furniture covers, boat covers, and other outdoor industrial uses. The durability of this protection ensures that the fabric will maintain its protective qualities over time, even under harsh environmental conditions.

Advanced Flame Retardancy: Meeting Global Standards

Beyond UV protection, safety is a paramount concern in many industrial applications. Our Flame Retardant Anti-UV Oxford Cloth is engineered to meet stringent safety standards, providing reliable flame retardant properties. During the production process, flame retardant powder is integrated into the polyurethane coating applied to the fabric. This ensures that the fabric meets the British Standard BS5852 for flame retardancy.

The integration of flame retardant properties into the fabric’s structure ensures that it can withstand exposure to open flames and high temperatures without igniting or melting, providing crucial protection in environments where fire hazards are present. This makes it an ideal material for use in ventilation ducts, industrial curtains, and protective covers in high-risk environments.

Enhanced Durability and Added Functionalities

Our Flame Retardant Anti-UV Oxford Cloth is designed with versatility and durability in mind. During the coating process, we can further enhance the fabric by adding additional functional properties. Anti-UV ingredients can be incorporated into the coating to provide even more robust UV protection, ensuring the fabric’s longevity in outdoor applications.

Moreover, we can also incorporate antibacterial agents into the coating. This addition is particularly beneficial for applications where hygiene and cleanliness are critical, such as in medical settings or environments where the fabric may be exposed to moisture and bacteria. The antibacterial properties help to prevent the growth of mold, mildew, and odors, extending the life of the fabric and maintaining its quality over time.

Wide Range of Applications

Our solution dyed fabric is highly versatile and suitable for a wide range of industrial and commercial applications. Its rugged construction and advanced protective properties make it an ideal material for furniture covers, boat covers, and ventilation ducts where exposure to harsh environmental conditions is a concern. Additionally, its flame retardant and antimicrobial properties make it a valuable choice for industrial drapes, protective clothing, and other applications where safety and hygiene are critical.

Customization and Cost Efficiency

At the core of our production philosophy is flexibility and customer-centric design. We understand that each application has unique requirements, which is why we offer customization options to meet your specific needs. Whether you require additional coatings, specialized finishes, or particular color specifications, our production process is designed to deliver high-quality fabrics that align with your exact specifications.

Moreover, our innovative manufacturing processes not only produce superior fabrics but also help in reducing raw material costs. By streamlining production and minimizing waste, we can offer competitive pricing without compromising on quality, ensuring that you receive the best value for your investment.

Conclusion

The Flame Retardant and UV Resistant Oxford Fabric is designed to meet the specific needs of various industrial applications. For furniture covers, it offers excellent UV protection, ensuring long-lasting durability in outdoor environments. In marine applications like boat covers, the fabric’s UV resistance is crucial for withstanding prolonged exposure to sunlight, though flame retardancy is not required in this context. However, for ventilation ducts and other industrial settings where fire safety is paramount, the fabric’s flame retardant properties provide essential protection. Our customizable approach ensures that the fabric meets the exact requirements of your application, delivering high-quality, functional solutions.