في صناعة الملابس الخارجية والنسيج، تُستخدم مصطلحات مثل "طارد للماء" و"مقاوم للماء" و"مضاد للماء" بشكل متكرر، ولكن لكل منها معنى مميز. وبدون فهم واضح لهذه المصطلحات، قد يكون من المحير للغاية اختيار القماش الذي يناسب احتياجاتك على أفضل وجه. على سبيل المثال، تستخدم بعض السترات المقاومة للماء معالجة خاصة لطرد قطرات الماء، بينما تعتمد أخرى على طلاء لمنع تغلغل الماء. بالإضافة إلى ذلك، توجد سترات مقاومة للماء تجمع بين مواد متعددة لمنع تسرب الماء تمامًا، وفي بعض الحالات، تحقق جميع وظائف مقاومة الماء الثلاث المختلفة في نفس الثوب. يمكن أن يساعدك فهم الاختلافات وطرق الاختبار المقابلة في اختيار القماش المقاوم للماء الأكثر ملاءمة لغرضك المحدد.

طارد المياه (WR)

ماذا يعني مصطلح "طارد للماء"؟ تتسبب المنسوجات المعالجة بعامل نسيجي طارد للماء في تكاثف قطرات الماء وانزلاقها عن السطح، تمامًا مثل قطرات الماء على ورقة اللوتس، مما يجعل من الصعب اختراق الماء. يشير هذا إلى أن الجزء الداخلي من القماش ليس مقاومًا للماء تمامًا؛ يمكنه فقط صد الماء عند ملامسته وإسقاط قطرات الماء. تم تصميم المواد الطاردة للماء لمقاومة اختراق الماء، لكنها ليست مقاومة للماء تمامًا. بدلاً من ذلك، فهي تهدف إلى منع الماء من نقع السطح، مما يتسبب في تجمع الماء وانزلاقه. هذا يجعل المواد الطاردة للماء مثالية لمعدات وملابس الهواء الطلق التي تتطلب مقاومة للماء والتهوية.

تجدر الإشارة إلى أن فعالية الأقمشة المقاومة للماء قد تقل بمرور الوقت. بعد الغسيل، عادة ما يكون التجفيف بالمجفف ضروريًا للحفاظ على أدائها المقاوم للماء. لقد قمنا بتحسين الإضافات المقاومة للماء وإضافة عوامل الربط المتقاطعة لتعزيز متانة قدرة القماش على مقاومة الماء (قماش DWR) بشكل كبير.

طريقة الاختبار

تُستخدم اختبارات مقاومة الماء بشكل شائع في صناعة النسيج لتقييم أداء القماش.

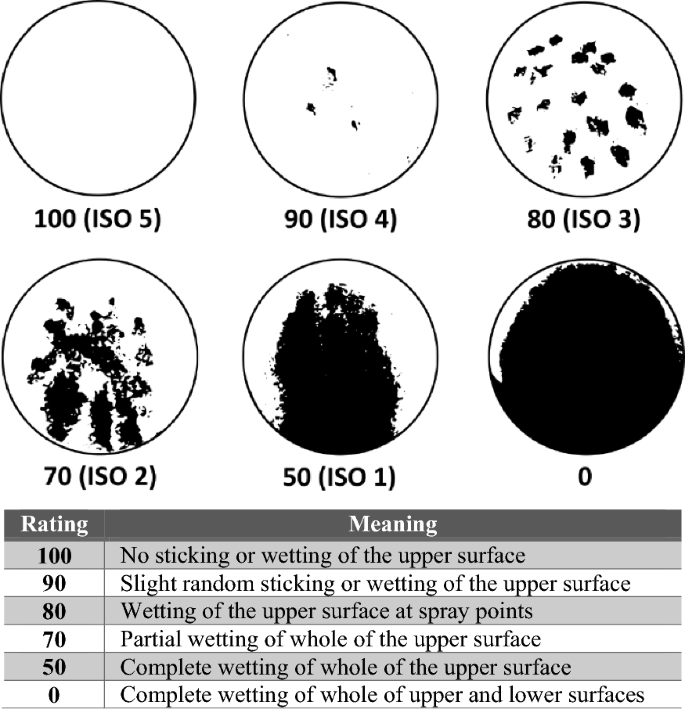

يمكن لاختبار الرش AATCC 22 تحديد معدل مقاومة القماش للماء. قم برش الماء على القماش الذي تم اختباره لفترة معينة وقم بتقييم مستوى مقاومة القماش للماء بناءً على رطوبة السطح. كلما قل اختراق القماش للماء، كانت قدرته على مقاومة الماء أفضل.

شرح التقييم

المحتوى ذو الصلة بتصنيف اختبار مقاومة الماء AATCC هو كما يلي:

مقاوم للماء

ما هو "مقاومة الماء"؟ يشير مصطلح "مقاومة الماء" إلى قدرة مادة أو طلاء مقاومة تغلغل المياه إلى حد معين. وهذا يعني أن المادة يمكنها تحمل المطر الخفيف أو رذاذ الماء دون أن تتشبع.

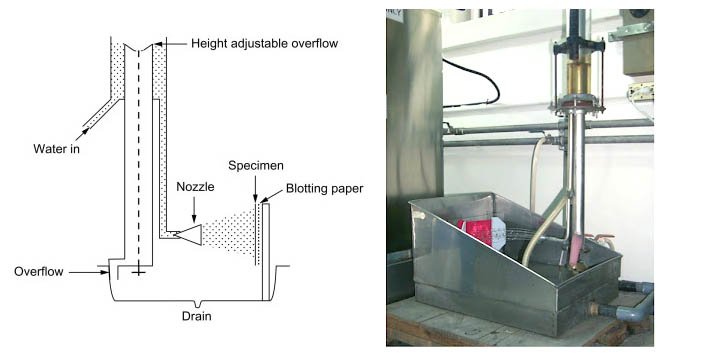

إذن، كيف نختبر أداء مقاومة الماء للسترة؟ اختبار مقاومة الماء AATCC 35 هو طريقة مستخدمة على نطاق واسع لتقييم قدرات مقاومة الماء. يحاكي سيناريو ممطر عن طريق وضع ورق ماص خلف القماش ورش الماء على النسيج عند مستوى ضغط عمود ماء معين. بعد وقت محدد، قم بقياس وزن الورق الماص قبل الاختبار وبعده. يعتبر الاختبار ناجحًا فقط إذا كان فرق الوزن أقل من 1 جرام. على الرغم من أن تأثير مقاومة الماء قد لا يكون هو نفسه تمامًا مثل تأثير المواد المقاومة للماء، إلا أن الأقمشة المقاومة للماء يمكنها مقاومة اختراق الماء تحت ملامسة الماء السريعة وضغط الماء.

وفيما يلي ثلاثة أمثلة لحساب الفرق في وزن الورق الماص قبل وبعد اختبار الأقمشة المقاومة للماء:

تقيس طريقة اختبار AATCC 35 أداء القماش المقاوم للماء من خلال تحديد كمية الماء التي تمر عبر المادة خلال فترة زمنية محددة. التفاصيل كما يلي:

| عينة | الوزن قبل الاختبار (جم) | الوزن بعد الاختبار (جم) | الفرق (ج) | توضيح |

|---|---|---|---|---|

| أ | 15.56 | 21.06 | 5.50 | يشير إلى مرور 5.50 جرام من الماء أثناء الاختبار |

| ب | 16.50 | 16.92 | 0.44 | يظهر أن كمية صغيرة فقط من الماء مرت عبر القماش أثناء الاختبار |

| ج | 16.82 | 39.47 | 22.65 | يعني أن كمية كبيرة من الماء مرت عبر القماش أثناء الاختبار، مما يشير إلى أن هذا القماش قد لا يكون مناسبًا للاستخدام في الظروف الرطبة |

لحساب فرق الوزن، قم ببساطة بطرح وزن الورق الماص قبل الاختبار من الوزن بعد الاختبار، ويمكنك الحصول على كمية الماء التي مرت عبر القماش أثناء الاختبار.

ضد للماء

غالبًا ما يرتبك العديد من الأشخاص حول ما إذا كان مصطلح "مقاوم للماء" هو نفسه "مضاد للماء". على الرغم من أن هذين المصطلحين قد يبدوان متشابهين للوهلة الأولى، إلا أن هناك اختلافات جوهرية في قدراتهما على مقاومة الماء. يكمن السبب الرئيسي وراء ذلك في الطريقة التي تحقق بها الأقمشة خصائصها المقاومة للماء. عادةً ما تتمتع الأقمشة المصنفة على أنها "مقاومة للماء" بدرجة معينة من مقاومة اختراق الماء، غالبًا من خلال معالجات السطح التي تتسبب في تجمع الماء وتدحرجه. من ناحية أخرى، تحقق الأقمشة "المقاومة للماء" عادةً مستوى أعلى من الحماية من خلال دمج الطلاءات أو أغشية مقاومة للماء مغلفة. تعمل هذه العناصر الإضافية على تعزيز قدرة القماش على منع تسرب الماء بشكل كبير، مما يضمن الحماية الكاملة ضد دخول الماء حتى في ظل الظروف الأكثر صعوبة.

إن تحقيق مقاومة طبيعية للماء أمر صعب للغاية. تستخدم معظم المنسوجات اختبار الضغط الهيدروستاتيكي المقاوم للماء AATCC 127 لقياس قدرتها على مقاومة الماء. يطبق هذا الاختبار ضغط الماء على مقدمة القماش حتى تظهر ثلاث قطرات من الماء على الظهر. كلما زاد ضغط الماء في الاختبار، كان أداء مقاومة الماء أفضل.

على سبيل المثال، يعادل تصنيف مقاومة الماء البالغ 20000 مم من الماء القدرة على تحمل ضغط ماء يبلغ 20 مترًا. وهذا هو معيار الأداء المقاوم للماء للأقمشة المستخدمة في العديد من ملابس تسلق الجبال والتزلج، مما يوفر حماية مثالية ضد الماء.

كيفية تفسير نتائج اختبار AATCC 127

فيما يلي أمثلة لنتائج اختبار النسيج من اختبار الضغط الهيدروستاتيكي المقاوم للماء AATCC 127 لأربعة أقمشة مختلفة:

| قماش | الضغط الهيدروستاتيكي | نتيجة الاختبار | الاستخدام المقترح |

|---|---|---|---|

| القماش أ | 20000 ملم من الماء | مناسب لسيناريوهات مقاومة الماء عالية الطلب | مثالية للسترات ذات القشرة الصلبة و جيش الملابس، حيث يعتبر الأداء الممتاز المقاوم للماء أمرًا بالغ الأهمية |

| القماش ب | 10000 ملم من الماء | يوفر حماية جيدة ضد الماء | مناسب للسترات ذات القشرة الناعمة ومعاطف المطر، والتي تتطلب توازنًا بين المرونة والمقاومة للماء |

| القماش ج | 3000 ملم من الماء | يوفر العزل الأساسي للماء | مناسب لملابس التنقل، حيث يمكنه تحمل المطر الخفيف أثناء السفر اليومي |

| القماش د | 1600 ملم من الماء | يلبي متطلبات مقاومة الماء معينة | اختيار جيد ل الخيام، حيث يمكنه الحماية من الظروف الجوية العادية |

لمعرفة المزيد عنا نايلون أو البوليستر أقمشة مقاومة للماء من فضلك اتصل بنا الآن.